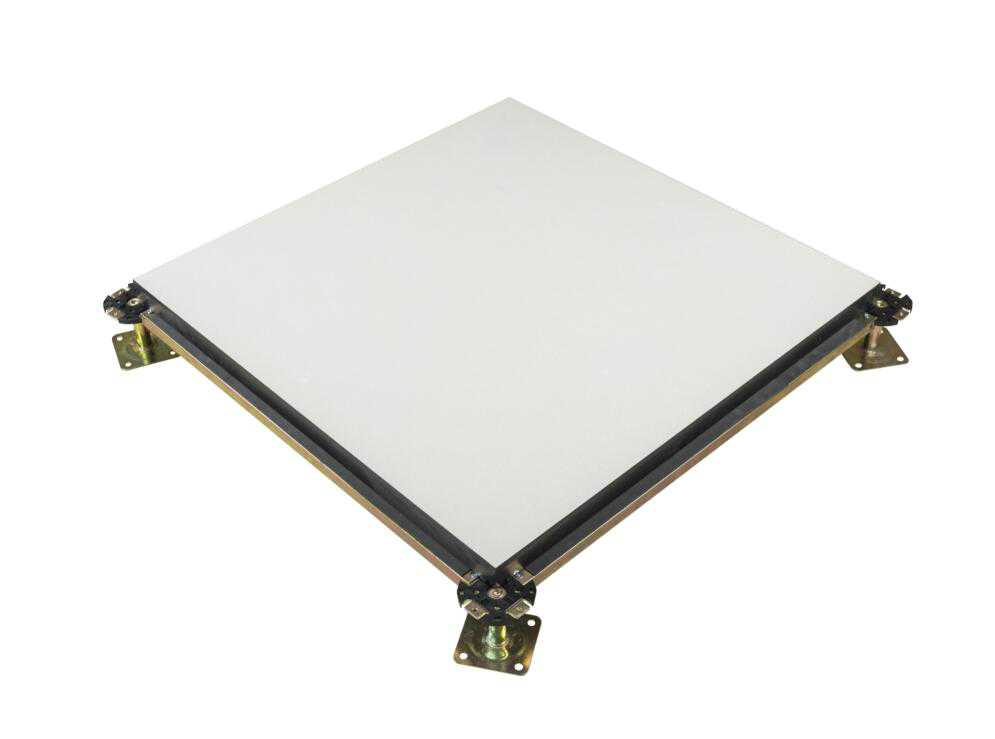

Type: | FS662-1500 |

Finished Floor Height: | 70-2000mm |

Panel Size: | 600*600mm、800*800mm and special size |

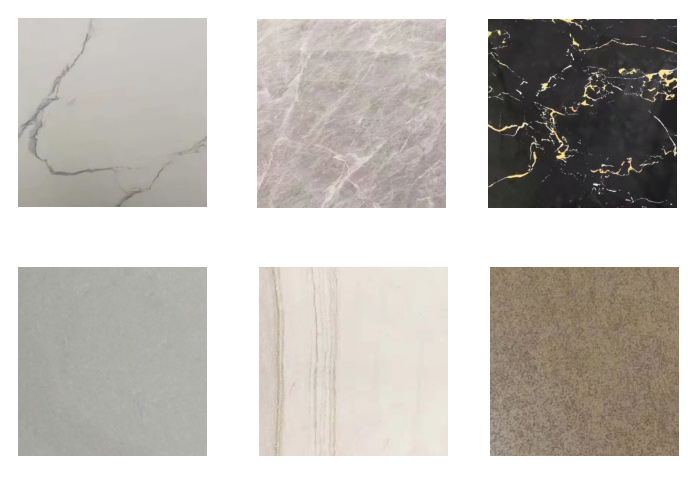

Ceramic Thickness: | 10/12mm |

Ceramic Type: | Normal ceramic and Anti-static ceramic |

Type | Size | Concertrated Load Defleation≤2.5mm | Uniform Load | Ultimate Load | System Resistance | ||

mm | LBS | KN | KG | KN/㎡ | KN | Ω | |

FS662 | 600*600 | 662 | 2.95 | 300 | 12.50 | 8.85 | 1.0x106-1.0x109 |

FS800 | 800 | 3.56 | 363 | 16.10 | 10.68 | ||

FS1000 | 1000 | 4.45 | 454 | 23.00 | 13.35 | ||

FS1250 | 1250 | 5.56 | 567 | 33.00 | 16.68 | ||

FS1500 | 1500 | 6.67 | 680 | 34.50 | 20.02 | ||

FS2000 | 2000 | 8.90 | 906 | 46.00 | 26.70 | ||